How to Choose the Best Emulsion Bottle for Skincare Products

In today’s competitive skincare market, packaging is more than a container—it is a critical part of product performance, brand identity, and the overall consumer experience. Among the many packaging formats available, emulsion bottles stand out as a premium choice for lotions, emulsions, essences, and lightweight creams. With countless shapes, materials, and dispensing systems on the market, choosing the right emulsion bottle can directly influence your product’s quality, stability, and market success.

Whether you are launching a new skincare line or upgrading your current packaging, this guide will help you understand how to select the best emulsion bottle for your formula and brand.

1. Understand Your Skincare Formula First

The starting point for choosing the right emulsion bottle is always the formula itself. Different formulations have different sensitivity levels and packaging requirements.

Key considerations:

• Viscosity: Thicker lotions require stronger pumps or more flexible bottle walls.

• pH and ingredient compatibility: Certain actives may react with specific plastics.

• Light sensitivity: Formulas with Vitamin C, retinol, AHAs, or botanicals may require opaque or tinted bottles.

• Preservation needs: Some emulsions need airtight or airless packaging to stay stable.

By matching your formula’s characteristics with the right packaging technology, you ensure product safety and long-term stability.

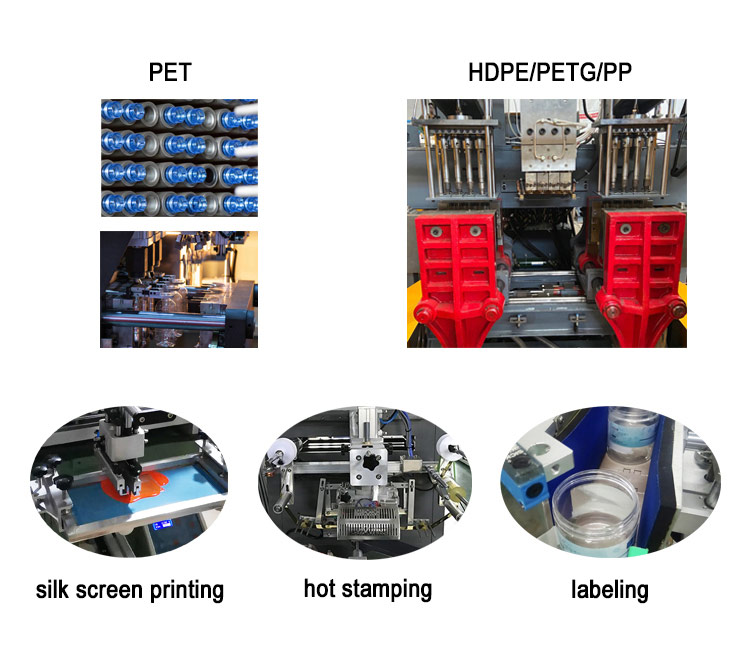

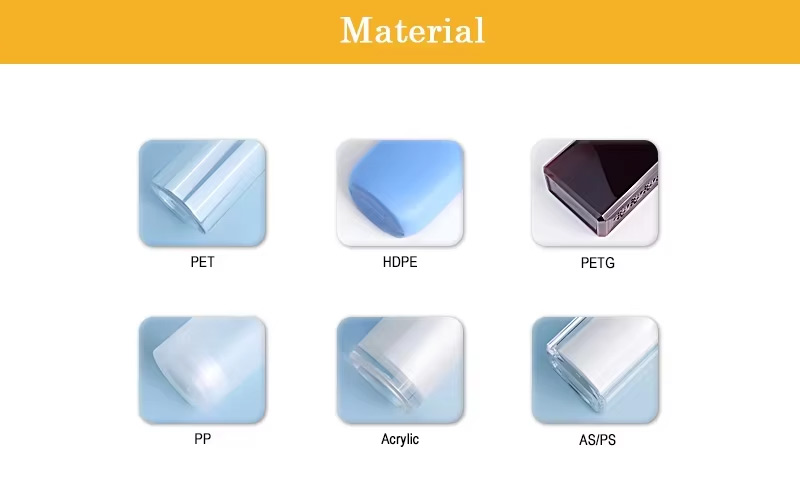

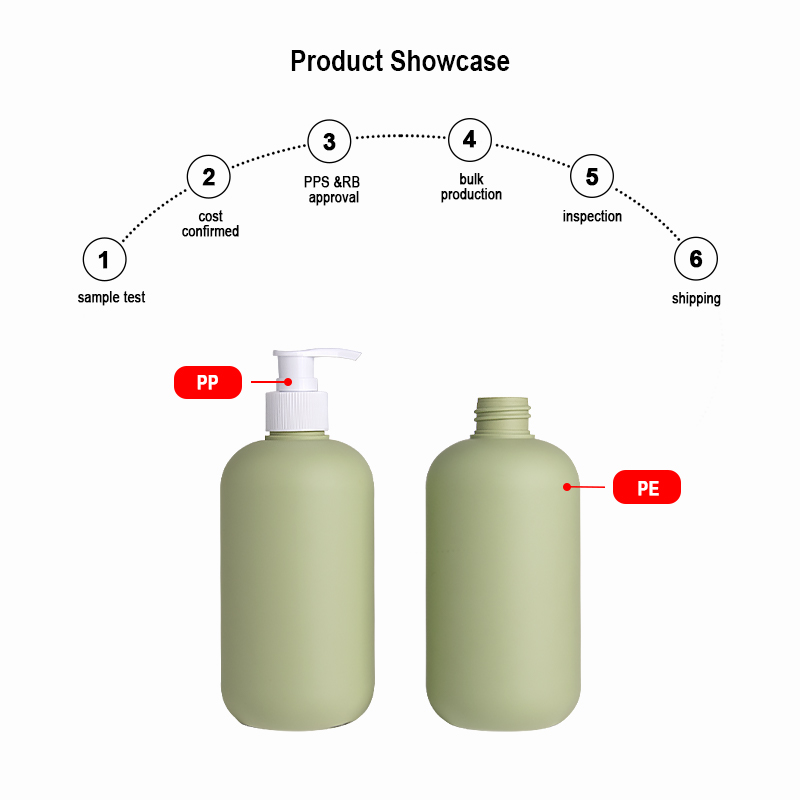

2. Choose the Right Bottle Material

Emulsion bottles come in various materials, each offering different levels of durability, aesthetics, and sustainability.

Common material options:

• PET (Polyethylene Terephthalate)

Lightweight, clear, and impact-resistant

Great for showcasing liquid or translucent skincare

Widely recyclable and cost-effective

• PP / PE (Polypropylene, Polyethylene)

Excellent chemical resistance

Ideal for thicker emulsions and lotions

Suitable for mono-material packaging aimed at recyclability

• Acrylic (PMMA)

High transparency, premium glass-like look

Good for luxury skincare lines

Best for non-light-sensitive products

• Glass

Premium aesthetic and excellent barrier properties

Suitable for high-end serums and emulsions

Heavier and more fragile but highly sustainable

• PCR (Post-Consumer Recycled) Plastics / Bio-based Materials

Eco-friendly option for environmentally conscious brands

Supports sustainability goals without sacrificing quality

Your material choice should balance functionality, brand positioning, and environmental responsibility.

3. Select the Appropriate Pump or Dispensing System

The dispensing system directly affects how consumers experience your product. The right pump ensures smooth, controlled, and hygienic application.

Popular options include:

• Lotion Pump

Suitable for medium to high-viscosity emulsions

Offers precise dosage and easy one-hand use

• Airless Pump

Protects sensitive formulations from air and oxidation

Ensures nearly 100% product evacuation

Ideal for natural, organic, or preservative-light skincare

• Mist or Spray Pump

Perfect for lightweight emulsions, toners, and moisturizing sprays

Produces a fine, even application

• Dropper or Serum Pump

Suitable for fluid or semi-fluid emulsions

Offers a premium, skincare-focused user experience

Picking the correct dispenser enhances product performance and reduces waste.

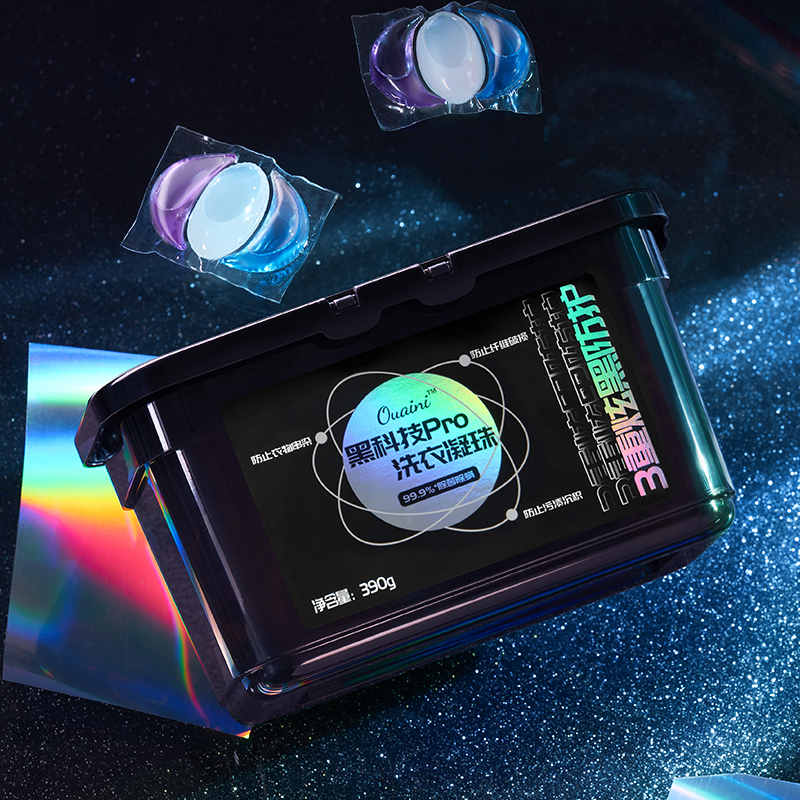

4. Consider the Bottle Shape and Aesthetic

Skincare packaging needs to align with your brand’s identity and stand out on the shelf.

Factors to keep in mind:

♣ Shape: Round, square, oval, or slim designs influence ergonomics and shelf appeal.

♣ Finish: Matte, glossy, frosted, metallic, gradient, or soft-touch textures.

♣ Decoration: Silk-screen printing, hot stamping, UV coating, labeling, heat transfer printing.

♣ Color: Transparent, tinted, solid color, or customized to match your branding.

A well-designed bottle enhances perceived value and strengthens brand recognition.

5. Think About Sustainability Requirements

Modern consumers increasingly prefer eco-friendly beauty products. Brands can adopt sustainable packaging strategies through:

♦ Mono-material designs that improve recyclability

♦ PCR plastics that reduce virgin material usage

♦ Lightweight bottle structures that cut carbon footprint

♦ Refillable packaging systems for long-term use

Selecting a sustainable emulsion bottle not only supports your brand's environmental goals but also appeals to conscious consumers.

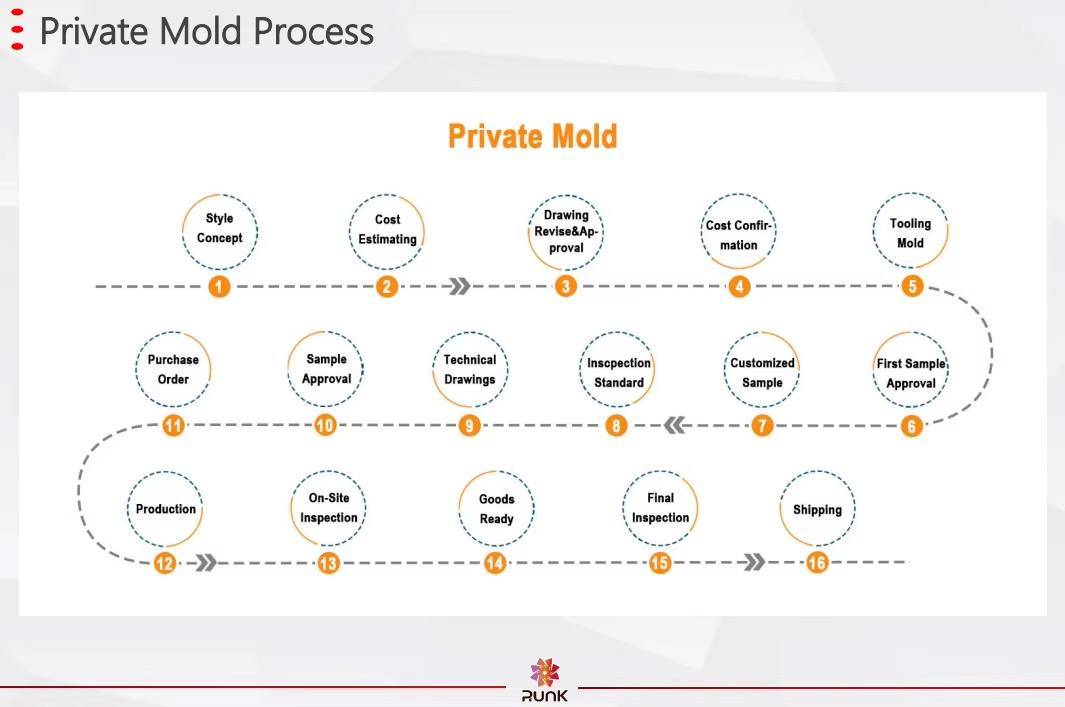

6. Evaluate Cost, MOQ, and Production Lead Time

When choosing packaging for large-scale or limited-edition skincare products, practical factors must also be considered:

♥ MOQ (Minimum Order Quantity): Depending on customization level

♥ Cost efficiency: Balance quality with budget

♥ Lead time: Custom molds or decorations require longer production times

♥ Filling compatibility: Ensure the bottle works smoothly with your filling line

Understanding these operational details helps prevent delays and unexpected expenses.

Conclusion

Choosing the best emulsion bottle for skincare products involves balancing formula requirements, functional design, aesthetics, sustainability goals, and cost considerations. With the right combination, your packaging not only protects the product but also elevates the entire user experience and enhances your brand’s market positioning.

Whether you need airless bottles for active-rich emulsions, luxury acrylic bottles for high-end creams, or eco-friendly PET/PCR options for mass-market skincare, selecting the right packaging partner --Runk is key to delivering quality and consistency.